3V Tech Process Equipment

About 3V Tech

Combining process and engineering know-how with its manufacturing capabilities, 3V Tech positions itself in the market of advanced process solutions and process equipment.

The company avails two design and manufacturing sites, with a total covered surface more than 16.000 m2. 3V TECH operates their own 2,000 m2 testing facility where pilot plant trails can be carried out to confirm simulations and tests of their equipment and process solutions against real products, ensuring that all client requirements are fulfilled.

Related Video

With our 3V TECH products we can offer our clients high quality, turn-key solutions

- Qualifications: ASME (U-stamp), PED, SQL, DIN EN ISO 3834-2 (glass-lining), ATEX 94/9/CE, SELO LICENSE

- Design codes: ASME, EN 13445, ISPESL, AD 2000, CODAP, SVT

- Available materials: Carbon Steel, 304 or 316 SS, Duplex SS, Superduplex SS, Hastelloy, Nickel based alloys, Nickel, Titanium, glass-lined, etc.

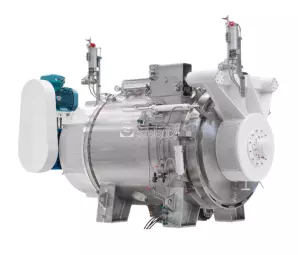

3V Tech main product types

Solid-liquid separation

Rotary filter-dryers

Leaf filters

Rotary pressure filters

Vacuum drying

Vertical conical dryers

Vertical pan dryers

Horizontal paddle dryers

Evaporation

Thin film evaporators

Falling film evaporators

Short path evaporators

Glass lined equipment

Reactors

SiC S&T heat exchangers

Biconical drryers

Nutsche filters

Storage Tanks

Columns

Product advantages

Glass coating which can be antistatic, abrasive resistant

Advanced coating technology

Complete solutions for chemical plants

Lab scale testing for preliminary screening and equipment selection

Pilot plant trials for scale-up to industrial units, design of optimal operating conditions

Highly qualified testing personnel

In-house test facilities and mobile rental units

Physical-chemical analysis of product samples

Detailed testing reports

Large sample quantity for customer's further R&D activities

Development of particular equipment, plants and processes for your application

Multi-step test plants can be set-up

Wide thermal and chemical resistance range

Product constructions

Robust construction

Highly corrosion resistant

Glass inner coating

Antistatic and/or and abrasion resistance coating

Skid mounted

Weather resistance

Stainless steel body

Heated shell

Energy efficient

Great value

Outstanding performance

Multiple solutions in one machine